Amino Acid Technology Innovation

Anhui BBCA Biochemical Co., LTD., currently has the provincial postdoctoral scientific research workstation, Bengbu municipal enterprise technology center two research and development institutions, The technology research and development team including microbial experiment group, fermentation technology research group, extraction technology research group, analysis group and information research group, a total of 29 people, a postdoctoral in station, and existing all kinds of advanced equipment more than 100 sets.

In 2021, postdoctoral scientific research workstation by industry-university-research cooperation with Anhui Science and Technology University, is committed to the amino acid fermentation tail fluid and by-products’ research and reuse, has carried out "research and application of key technology of amino acid fermentation tail liquid preparation for organic & inorganic compound fertilizer and ecological Chu chrysanthemum cultivation" research and development project, in March, the project successfully applied for the provincial science and technology major project, and has preliminary passed; In July, the project was successfully applied for the Anhui Division of the National Postdoctoral Innovation and Entrepreneurship Competition.

In the year of 2018-2020, the technology research and development team combined with the company's organic acids, amino acids, polylactic acid, sodium gluconate and other products for the research and development of related projects, through the transformation of the project results, currently has been applied for “an L-alanine fermentation production method”, “a method of separating & purifying lysine fermentation solution”, “a method of fermentation production of erythritol”, “an extraction method of L-threonine acid”, “an extraction method of L-glutamine”, “an extraction method of L-alanine”, “a production method of D-aspartic acid”, “an crystallization method of aspartic acid”, “an fermentation method of arginine”, “method of one-step conversion to lactide”, “a method of recovering lactic acid from lactic acid distillation kettle bottom liquid” and other 11 patents.

In Anhui province scientific and technological achievements registration system has been successfully registered: “L-lysine fermentation method research”, “L-threonine new production process research”, “study on optimization of starch emulsion sugar production process”, “lysine production concentrated membrane phase comprehensive utilization research”, “sodium gluconate process research and development project”, “98% lysine production process optimization research” and so on six results, which have received results registration certificate.

In 2021, BBCA Biochemical has carried out “L-lysine membrane concentrated phase extraction technology research”, “new process of sodium gluconate”, “study on yield improvement of corn gluten meal” and other research projects, plans to carry out “L-lysine continuous cross resin selection technology research”, “L-threonine new production process research and development”, “starch milk sugar, improve the quality of sugar liquid new technology”, “secondary condensate film treatment process” and other research projects.

Polylactic Acid Technology and Innovation

BBCA Biochemical relies on the platform of National Engineering Research Center of Fermentation Technology, in cooperation with domestic universities and research institutes, it has jointly established Anhui polylactic acid New Materials Manufacturing Innovation Center, Anhui Province Technology Innovation Center for Biodegradable Materials, and Anhui Province Technology Standard Innovation Base for bio-based polymeric Materials.

Pollactic acid has high quality requirements for raw material lactic acid. There are three strains of high-quality lactic acid industrial bacteria with independent intellectual property rights, which belong to Purac, the Netherlands, Galactic Belgium (the Belgian partner of BBCA Biochemical) and BBCA Group.

BBCA Biochemical, NatureWorks of Cargill USA, and Total Corbion, a joint venture between Purac and Total France, are the only three manufacturers in the world with a whole industry chain from sugar to polylactic acid.

As early as in 2004, BBCA group has imported the Belgian Galactic Company, which has the world's advanced production technology of L-lactic acid bacteria and its derivatives, to China. At present, BBCA has fully mastered the core technology and production management experience of the whole industrial chain, including lactobacillus species selection, fermentation control, separation and purification, polymerization reaction, and the downstream application and development of polylactic acid (environmentally friendly fiber, environmentally friendly plastic, environmentally friendly wood panel preparation).

At present, 150,000 tons / year lactic acid, 100,000 tons / year polylactic acid (phase I) production lines of BBCA Futerro have been completed and put into operation.

BBCA Independent Research and Development of the Whole Industrial Chain Polylactic Acid

BBCA group after nearly 20 years in the core technology and downstream application of continuous research and development, in addition to the lactic acid and polylactic acid technologies that the company has cooperated with Galactic Belgium, the company also cooperated with domestic research institutions and colleges to integrate the technology of the whole industrial chain. On November 8, 2019, the company successfully put into trial operation the industrial demonstration line of 5,000 tons/year lactic acid and 3,000 tons/year polylactic acid built with its own high-yield lactic acid fermentation strain.

This is a national leading whole industry chain of lactic acid and polylactic acid production line starting from glucose fermentation.

BBCA Biochemical creatures controlled adjustable molecular weight polylactic acid, which discrete index is low, can be adjusted according to the downstream application, low cost, in addition, it has opened up the core technologies in the application fields of PLA textile, injection molding, film blowing and profiles, which can provide technical support for downstream application enterprises and lay the foundation for the large-scale development of PLA industry.

BBCA Biochemical is a global manufacturer that has mastered two sets of polylactic acid production technology in the whole industrial chain, technology cooperation with Galactic Belgium has been globally exclusive, Including a full range of technology from bacteria to lactide, polylactic acid; BBCA independent intellectual property rights of domestic polylactic acid whole industry chain technology, system mastered the L-lactic acid production and “a kind of lactic acid bacteria fermentation method”, “a method of continuous production of L-lactic acid fermentation”, “a preparation method for high molecular weight polylactic acid”, “a method of producing D-lactic acid from fiber hydrolysate”, “a method of mutagenesis and breeding of lactic acid bacteria”, and 5 invention patents have been authorized, more than 10 are being declared.

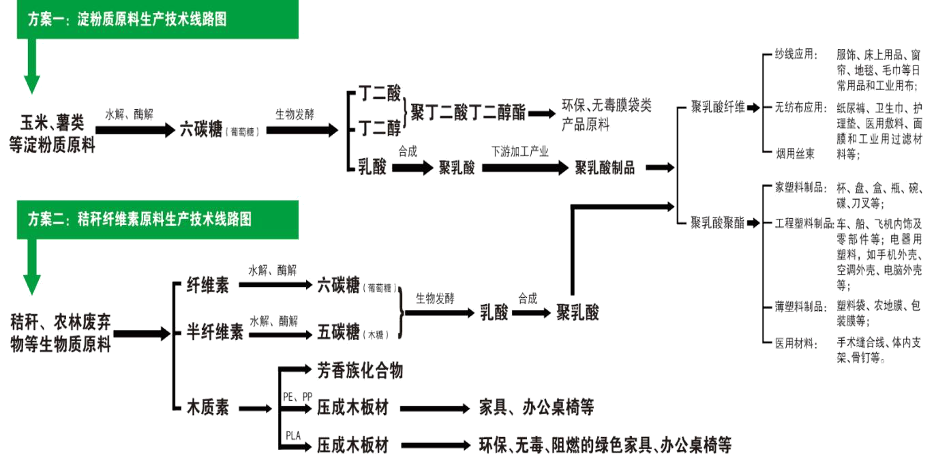

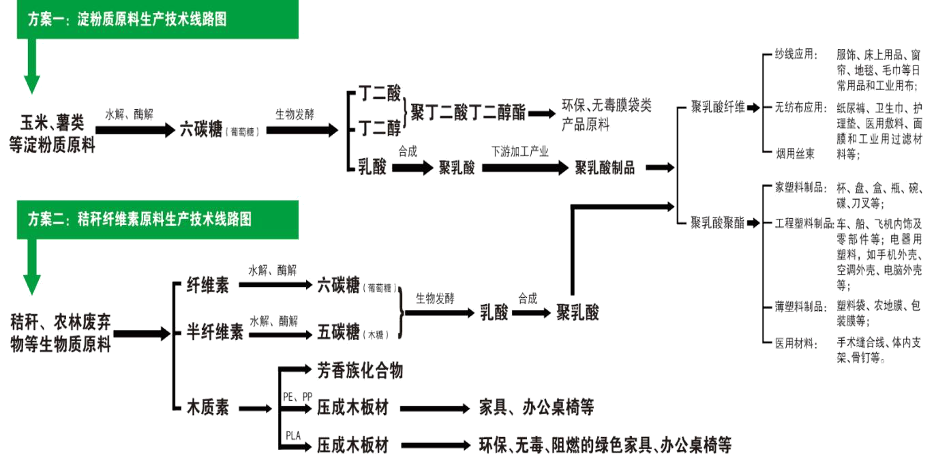

Reserved Technology: Using Straw to Generate PLA

BBCA also reserves the technology to use straw cellulose to produce PLA. As early as 2010, BBCA Group built an industrial demonstration project that used corn straw as raw materials to produce 5000 tons/year of fuel ethanol and 1000 tons/year of lactic acid. And passed the acceptance of the Department of Science and Technology of Anhui Province.

After the PLA industry has developed to a large scale, in response to market competition and raw material supply pressure, BBCA Biochemical plans to use crop straws as raw materials to produce PLA series products after 2025. Ensure the sustainable and rapid development of the new bio-based material PLA industry.

淀粉质原料和秸秆纤维素技术

皖公网安备34032302020386号

皖公网安备34032302020386号