The Application of Polylactic Acid

--Product Demonstration and the Guidance Use of Each brand

1. The Main Use of Polylactic Acid Products - Green Fiber

Green Fiber — replace petrochemical fiber (PET, PBT, PTT, etc.)

The fabric made of polylactic acid fiber has a weak acid similar to human skin. It is naturally skin-friendly, antibacterial, anti-mite, has good drape, moisture permeability, luster and silky feel, and anti-ultraviolet function, which has significant advantages when used in underwear, sports and leisure clothing, and bedding production.

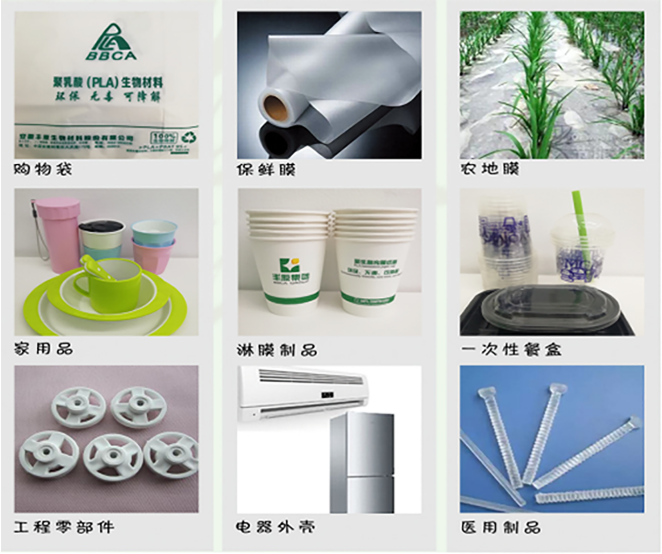

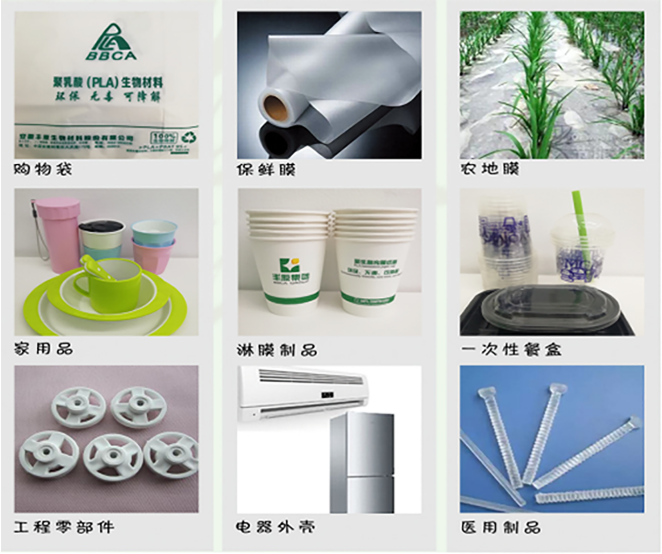

2. The Main Use of Polylactic Acid Products - Green Plastic

Green plastics — replace petroleum plastics (PE, PP, PVC, etc.)

Polylactic acid can be made into household plastics (cups, trays, boxes, bottles, etc.), industrial plastics (cars, boats, aircraft interiors and parts, home appliances shells, etc.), film plastics, medical materials (surgical thread, bone nails, etc.) through extrusion, injection, blow molding and other processes. Polylactic acid is safe, non-toxic, and has good biocompatibility. It is a biodegradable material with excellent antibacterial and antifungal properties, and it is also the main material for 3D printing.

Every year, the global food packaging industry consumes more than 67 million tons of plastic, and there is huge room for substitution.

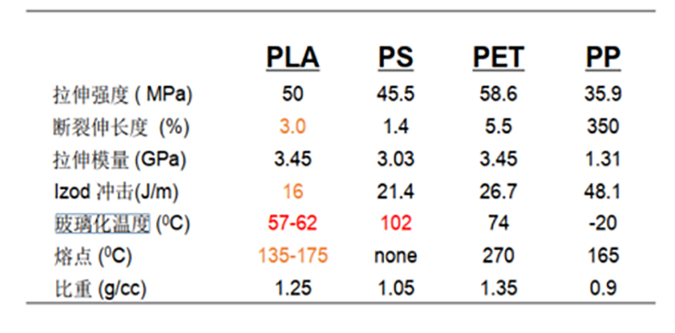

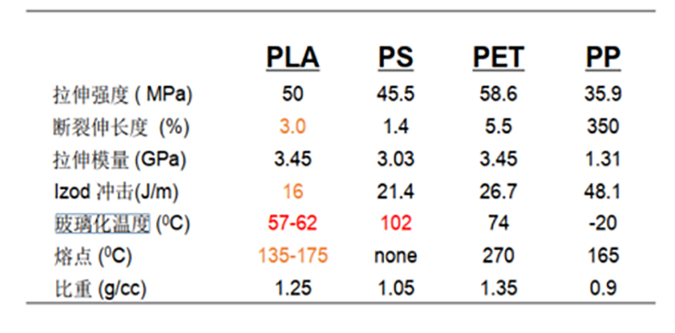

3. Mechanical Properties of PLA

The mechanical properties of polylactic acid are similar to those of polystyrene (PS)

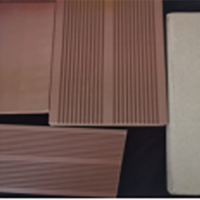

4. The Main Use of Polylactic Acid Products - Green Board and Bio-PU

Bio-PU - BBCA has supplied polylactic acid polyols to the market for the production of Bio-PU, which can be used in a variety of fields such as artificial leather, oil film, hard foam and soft foam. We have mastered the technology of biobased lysine isocyanate production, and can provide the whole biobased polyurethane series products to the market in the future.

Green Board - BBCA currently reserves the technology to use straws to produce polylactic acid. About 4 tons of straws produce 1 ton of polylactic acid and 1 ton of wood plastic materials. Wood plastic materials produced by using polylactic acid as a binder do not contain bisphenol A and formaldehyde (urea-formaldehyde resins, phenolic resins), and are widely used in indoor and outdoor decoration, furniture manufacturing, office furniture, etc.

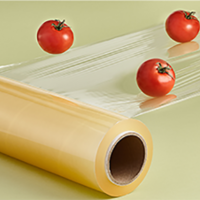

5. Main Use of Polylactic Acid Products - Bidirectional Stretching Film

Polylactic acid bidirectional stretching film (BOPLA) - Bidirectional stretching film is the orientation of the polymer molecule through the longitudinal and transverse mechanical stretching of the plastic film, which improves the crystallinity of the polymer molecules and the refinement of crystallization, thus greatly improving the mechanical strength and transparency of the bidirectional stretching film. BOPLA has been successfully mass-produced, with the downstream application market in China alone exceeding 10 million tons/year.

All kinds of conventional printing and non-printing, heat sealing and non-heat sealing packaging films - smoke film, outer packaging film, adhesive tape, protective film, kink packaging, all kinds of shrink packaging, refrigerated anti-fogging anti-UV irradiation preservation packaging, BOPLA aluminum plating, aluminum plastic, paper plastic, plastic-plastic composite.

皖公网安备34032302020386号

皖公网安备34032302020386号